Cerámica de alúmina Shengfan:

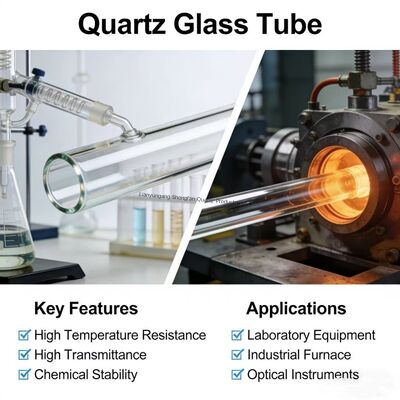

Somos un fabricante de hornos de tubo de cuarzo transparente.

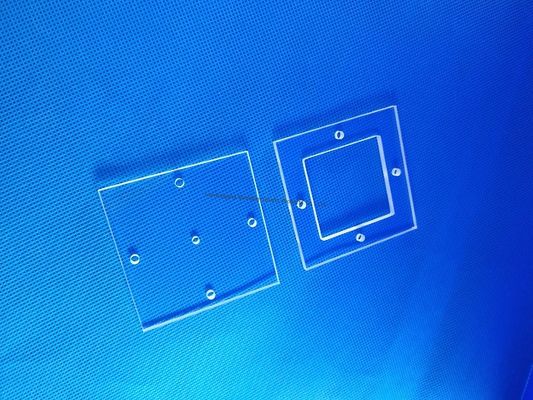

Tamaño y diseño: Aceptamos personalización según diferentes diámetros, espesores, longitudes o enviando su dibujo.

Descripción de productos:

Piezas de cerámica de alúmina se utilizan para piezas giratorias en y en máquinas de fotolitografía en estado de vacío. Esto requiere una precisión de mecanizado extremadamente alta, y se requiere que la descentración del círculo interior esté dentro de 2 micras.

La cerámica fina se ha convertido en componentes clave de los equipos de semiconductores. Especialmente en las máquinas de litografía de alta gama, para lograr una alta precisión del proceso, es necesario utilizar ampliamente componentes cerámicos con buena composición funcional, estabilidad estructural, estabilidad térmica y alta precisión dimensional. Tales como E-chuck, Vacumm-chuck, Bloque, placa refrigerada por agua con esqueleto de acero magnético, reflector, riel guía, etc.

Otras piezas cerámicas de alta precisión utilizadas en la industria de semiconductores. La cerámica de precisión se ha convertido en componentes clave de los equipos de semiconductores, incluidos hornos de monocristales, equipos de implantación de iones, máquinas de fotolitografía, equipos CVD/PVD y equipos de embalaje y prueba.

Innovacera puede proporcionar los materiales requeridos, incluyendo cerámica de alúmina, cerámica de nitruro de aluminio, cerámica de nitruro de silicio, cerámica de nitruro de boro//nitruro de boro pirolítico, carburo de silicio y cerámica microporosa.

Equipo de producción:

Perfil de la empresa:

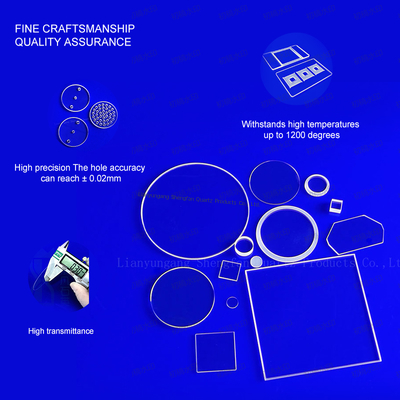

Lianyungang Shengfan Quartz and Ceramic Product Factory es un fabricante profesional especializado en la investigación y el desarrollo de placas de cuarzo, tubos de cuarzo, bridas de cuarzo, anillos de cuarzo, cubetas e instrumentos de cuarzo.

La empresa está ubicada en China Crystal Capital - Ciudad de Donghai, provincia de Jiangsu, China. A 70 km del puerto de Lianyungang, transporte conveniente. Cubriendo un área de 1000 metros cuadrados, ahora tenemos más de 30 empleados, una cifra de ventas anuales que supera los 5,2 millones de dólares estadounidenses. Con la filosofía de Orientación Tecnológica, Calidad Primero, Integridad y Responsabilidad, Operación Sostenible, la empresa se dedica a establecer una empresa internacional con capacidad de operación estándar y sostenible.

Embalaje:

Preguntas frecuentes:

P1. ¿Puedo tener un pedido de muestra? R: Sí, damos la bienvenida al pedido de muestra para probar y verificar la calidad.

P2. ¿Qué pasa con el tiempo de entrega? R: Dentro de los 15 días posteriores a la recepción del depósito.

P3. ¿Tiene algún límite de MOQ? R: MOQ bajo, 1 pieza para la verificación de la muestra está disponible

P4. ¿Cómo proceder con un pedido en su fábrica?R: En primer lugar, háganos saber sus requisitos o aplicación. En segundo lugar, cotizamos de acuerdo con sus requisitos o nuestras sugerencias. En tercer lugar, el cliente confirma las muestras y realiza el depósito para el pedido formal. En cuarto lugar, organizamos la producción.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!